- Gqeberha | South Africa

How smart asset monitoring maximised manufacturing efficiency

- Key Metrics Achieved

“Our process is not complicated, but that is the beauty about ODIN; it is beneficial for various industries and processes across the board… complex or simple.”

Rudi van den Berg | Managing Director

About The Customer

DynaFoam Converters (Pty) Ltd is the foremost supplier of pressed foam, felt and rubber components to the automotive industry, manufacturing more than four million components per month at their premises in the Coega Industrial Development Zone.

Specialists in their field of foam technology, the company, with the support of strategic partners, has been ensuring the supply of validated materials to all sectors since 2011. Their mission is to deliver quality pressed foam components that meet the required specifications to the South African and global market – on time, first time, every time.

Customer Requirements

DynaFoam wanted to gain data-driven insights into their machines and enable the team to identify areas for improvement in their current production processes.

1. Visibility and Performance Management

- Gain real-time insights into machine uptime, downtime, and utilisation.

2. Operational Efficiency

- Maximise productive machine time and reduce idle periods.

3. Data-Driven Production

- Identify and eliminate the causes of lost production time.

- Use historical trends to guide continuous improvement initiatives.

- Support better resource allocation with real-time utilisation data.

Key Challenges

Before ODIN Checkpoint, these are some of the challenges DynaFoam faced:

1. Poor Visibility into Machine Utilisation

- No clear view of how effectively machines were being used.

- Difficulty identifying when and why machines were idle or underperforming.

2. Production Losses

- No accurate baseline for performance, leading to misalignment between targets and output.

3. Lack of Accountability

- Without real-time monitoring, it was difficult to pinpoint where and when issues occurred.

- Operators and supervisors had limited tools to track performance against expectations.

4. Limited Production Planning Accuracy

- Poor machine visibility made it hard to schedule accurately or predict output capacity.

- Planners worked with assumptions rather than real data.

Our Solution

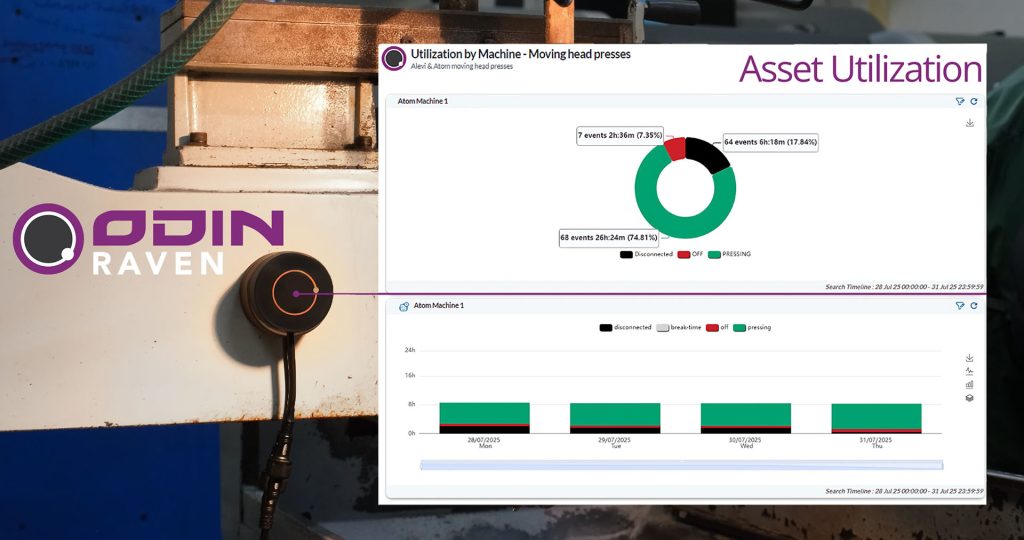

ODIN Raven, a vibration sensor, was configured to identify machine activity and downtime – with the goal of better utilising machine time and increasing the production rate.

Deployment Scope

An initial deployment of three Raven sensors was completed on site. The data provided immediate visibility into machine utilisation, enabling rapid optimisation. Within just three weeks, production output increased from 26 to 90 foam rollers per hour – a remarkable 346.2% improvement in throughput. Over the next year, another six Ravens were deployed to further extend visibility and drive continuous improvement to the rest of the production facility.

Customer Benefits

- Quick and non-invasive deployment: The sensor was quick to deploy and required no physical connection to machines or integration with existing applications, ensuring minimal disruption to operations.

- Proactive issue detection: Highlighted periods of inactivity during scheduled production, allowing for immediate investigation and action.

- Data-driven insights: Visual timelines revealed exactly when and where production downtime occurred, helping managers pinpoint bottlenecks and inefficiencies.

- Loss recovery opportunities: Clear visibility into lost production time empowered teams to take corrective measures and recover valuable output.

- Enhanced decision-making: Access to

accurate utilisation data supported better planning and prioritisation.

Key Takeaways

By implementing ODIN Raven, the customer significantly increased production efficiency through smarter machine utilisation. Real-time performance monitoring, actionable insights, and optimised planning enabled the team to reduce downtime, boost throughput, and make better use of existing resources – without additional capital investment.