Transform your operations with our workforce productivity app

It’s the smarter way to get the basics right.

ODIN Checkpoint is a cloud-based solution for improving your facilities management that supports:

![]() paperless maintenance task management app

paperless maintenance task management app![]() management of unplanned incidents

management of unplanned incidents![]() live production tracking, and

live production tracking, and![]() asset condition monitoring with ODIN Raven our AI-enabled vibration sensor.

asset condition monitoring with ODIN Raven our AI-enabled vibration sensor.

MODERN & SCALABLE ARCHITECTURE

ODIN Checkpoint let’s you start with a single asset and scale to thousands as you need. Make use of the mobile app or use the web app in browser. From task management to planning and reporting, Odin Checkpoint has you covered.

START SMALL

ADOPT

PROVE VALUE

SCALE

START SMALL

ADOPT

PROVE VALUE

SCALE

Perfect for all industries

of all sizes

Start with a single asset and scale to thousands as needed. ODIN Checkpoint’s modern and scalable architecture includes:

![]() a task management app (mobile)

a task management app (mobile)![]() a planning and reporting web app

a planning and reporting web app![]() an add-on vibration condition monitoring sensor

an add-on vibration condition monitoring sensor

How ODIN Checkpoint can transform your operations

Decrease downtime with real-time alerts to the right people

Our alert system can be activated manually by a technician or automatically by our vibration sensor.

Your team can log, track and respond to unplanned issues such as breakdowns, part shortages and safety incidents more efficiently.

Create custom charts to identify and address high-frequency issues. Notifications and tasks are also automatically assigned and scheduled following a sensor alert.

Get control over your maintenance function

Empower your technicians to schedule and manage their tasks, whether preventative or reactive, and to provide instant feedback via the app.

Give technicians the tools to work smarter

Interactive work instructions and SOPs can include media such as videos and images for on-the-job guidance and training.

Digitise your non-production tasks

Go paperless with a dedicated task manager for verification checks, continuous improvement actions, and safety audits.

Track your production output digitally

Replace paper-based record-keeping with our user-friendly app. Live-track the trends for corrective action planning when targets aren’t met.

Find asset documentation fast with your digital filing cabinet

Get quick cloud access to all your critical asset and project documentation in one place. Just scan the QR code on the asset or log in to the app.

Enjoy access to live analytics

Get a real-time, bird’s-eye view of your plant performance and cut the time it takes to take action and report on planned and unplanned tasks.

Capture and share data with Rapid Records

This customisable, in-app feature allows your team to capture, organise and share text-based and numerical data efficiently and on the spot.

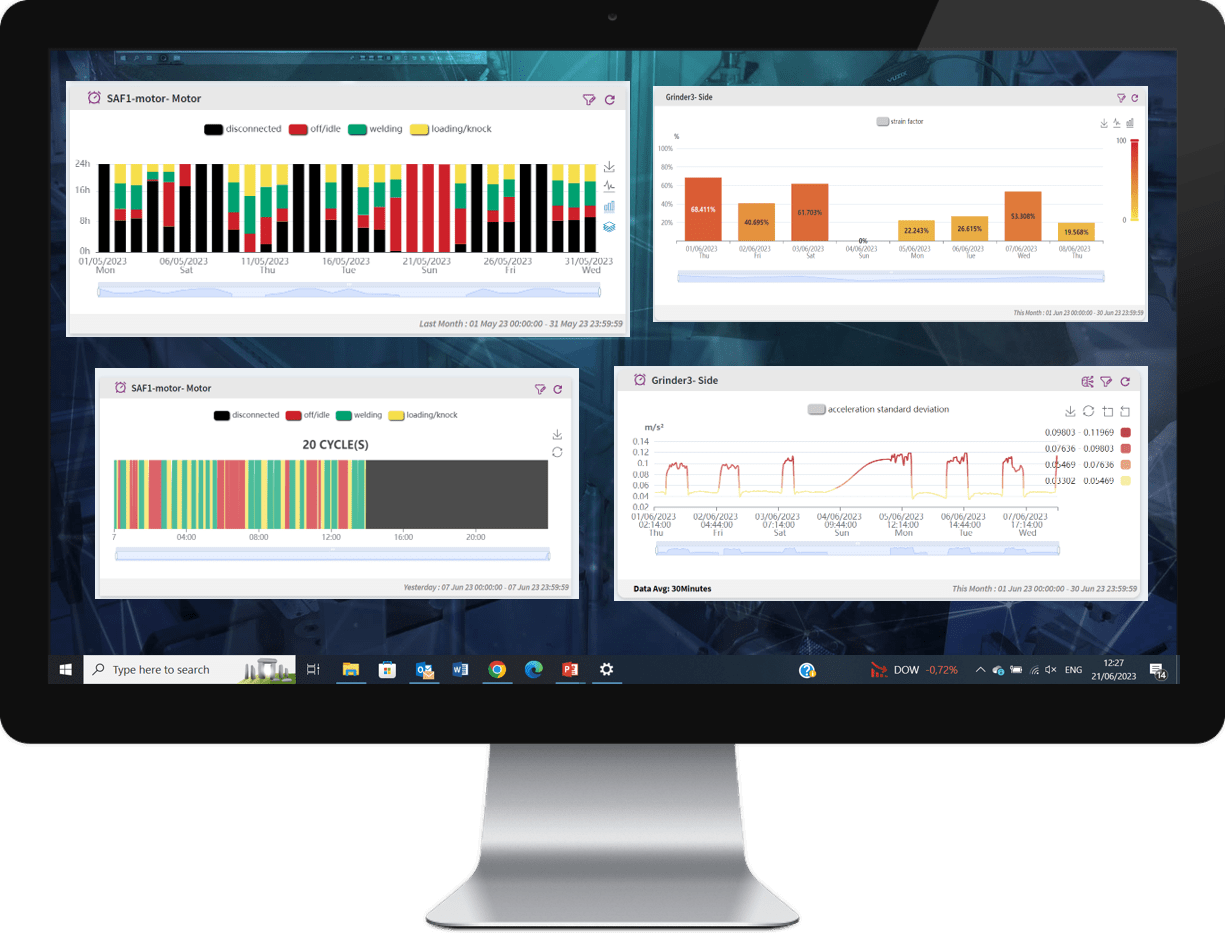

How ODIN Raven can unlock critical asset data

Use the data to:

- count asset cycles and cycle times

- detect high-risk anomalies

- monitor asset utilisation

- identify improvement opportunities

Make legacy assets smarter

Collect production performance and asset health data from new and old assets via a non-invasive, AI-enabled vibration sensor.

Solve equipment failures before they happen

Monitoring your asset health allows your technicians to take a proactive approach to asset maintenance and avoid unplanned downtime.

Get the most from your assets

Monitor your asset cycles and output, and find out if your equipment is being used to its full potential or if additional equipment is required.

Access your vibration data analytics

By onboarding your sensor to the ODIN Checkpoint dashboard, you can track asset usage and operation state, monitor asset cycles and output.

Use this data to predict potential failures, schedule preventative maintenance and optimise asset performance.

Get automatic alerts instantly

When the sensor detects an anomaly in the vibration patterns, the system automatically raises an alert and assigns a technician to attend to the problem.

Answering your questions

We answer some of ODIN Checkpoint and ODIN Raven's most frequently asked questions.

Why was ODIN Checkpoint created?

It started with a simple but critical insight – small tasks that go unnoticed can have a huge impact at the end of the day. Whether it’s a missed inspection or a delayed maintenance check, these gaps add up. ODIN Checkpoint was built to bridge them.

Why does my company need ODIN Checkpoint?

Because missed tasks, scattered systems, and unplanned downtime can cost more than you think. ODIN Checkpoint brings it all together – digitising

operations, boosting accountability, and improving performance across your facility.

How can ODIN Checkpoint reduce unplanned downtime in my facility?

When small issues go unnoticed, they lead to costly breakdowns. ODIN Checkpoint helps you stay ahead with real-time tracking and proactive maintenance.

What are the benefits of digitising maintenance task management?

From reducing human error to improving efficiency, going digital means fewer delays, better tracking, and smarter decision-making. Are you still relying on

paper? It’s time to upgrade.

Which industries could benefit from ODIN Checkpoint?

From manufacturing to agriculture and industrial servicing, ODIN Checkpoint helps businesses reduce downtime, streamline tasks, and improve efficiency. If

assets need to be maintained, ODIN Checkpoint can make a difference.

Will digital systems replace human workers?

The reality? Digital tools like ODIN Checkpoint don’t replace people – they empower them. By automating routine tasks, teams can focus on high-value work, improving efficiency and decision-making.

How long does it take to implement ODIN Checkpoint?

Implementation is quick and hassle-free. With our guided onboarding, most teams are up and running in a short timeframe.

Is going digital expensive and only for big companies?

The truth? Digital maintenance solutions are more accessible and cost-effective than ever. Whether you’re a small business or a large enterprise, ODIN Checkpoint scales to fit your needs.

What factors determine the cost of ODIN Checkpoint?

From facility size and number of assets to features and integrations, the cost is tailored to your needs, ensuring you only pay for what adds value to your operations.

Can we scale our plan as our business grows?

The answer is simple – yes! ODIN Checkpoint is built to adapt to your needs, whether you’re adding new facilities or increasing operations. Scale seamlessly, without disruptions.

How does ODIN Checkpoint's pricing module work?

Our pricing is flexible, designed to scale with your business. You pay for what you need – no hidden costs, no surprises.

What’s included in the base package?

Curious to know more about our base package? From core task management tools for real-time tracking and user-friendly dashboards, it’s everything you need to get started with ODIN Checkpoint.

What happens if we decide ODIN Checkpoint isn't the right fit?

We get it – not every solution fits every business. That’s why we keep things flexible. If ODIN Checkpoint isn’t right for you, we make offboarding simple and stress-free.

What kind of training and support do you provide for new customers?

From hands-on onboarding to ongoing support, we’re with you every step of the way to ensure a smooth and successful rollout of ODIN Checkpoint.

What should I do if I encounter an issue with ODIN Checkpoint?

From built-in support features to dedicated assistance from our team, we’re here to help you quickly resolve any issue and keep things running smoothly.

How do you gather and act on customer feedback?

At ODIN Checkpoint, your feedback is important. From feature updates to platform improvements, we’re constantly listening, learning, and evolving – so you get more of what works.

How do I contact support if I experience an issue?

Whether it’s through the app or email, our support team is just a message away – ready to help you resolve issues quickly and keep your operations running

smoothly.

Helpdesk email:

support@odinmanufacturing.io

Will my technicians and operators struggle to adapt to a digital system?

ODIN Checkpoint is designed for simplicity. With an intuitive interface and seamless onboarding, teams can start using it with minimal training – making their jobs easier, not harder.

Do we need an IT team to manage ODIN Checkpoint, or is support included?

You don’t need an in-house IT team. ODIN Checkpoint is fully supported by our team, making setup and ongoing management simple, seamless, and stress-free.

Do I need special hardware to use ODIN Checkpoint?

No special hardware required. ODIN Checkpoint works with most devices, making it easy to roll out without extra costs or complexity.

What kind of network or IT infrastructure is required?

ODIN Checkpoint is cloud-ready and lightweight, meaning it runs smoothly on standard networks – no complex infrastructure needed.

What is ODIN Raven?

ODIN Raven is our powerful AI-enabled vibration sensor that gives you real-time insights into asset health and performance.

How does ODIN Raven's vibration monitoring prevent equipment failures?

By continuously tracking vibration patterns, ODIN Raven detects anomalies, helping you take action before a breakdown happens – saving time, money, and downtime.

Can ODIN Raven be used with older equipment?

Absolutely. ODIN Raven is designed to retrofit easily onto legacy machines, giving you powerful vibration insights without the need for costly upgrades or replacements.

Is ODIN Raven difficult to install?

Not at all. ODIN Raven is designed for fast, hassle-free installation, so you can start monitoring your equipment with minimal downtime and no complex setup.

How often do you release updates?

We believe in continuous improvement. That’s why ODIN Checkpoint gets regular updates based on user feedback and evolving industry needs – so you

always have the best version at your fingertips.

How do you prioritise new features in ODIN Checkpoint?

Our roadmap is shaped by real user needs, on-the-ground feedback, and long-term impact. Every update is focused on delivering the most value where it matters most.

What is one feature that is under utilised that has huge potential?

Some features fly under the radar – but they’re game changers. This video spotlights the documentation portal that could dramatically boost efficiency if more teams took full advantage of it.

Can you share a example of a feature that had a significant impact on ODIN Checkpoint users?

From improving visibility to reducing downtime, one powerful feature helped teams stay on top of tasks and act faster – proving how the right tools drive real change on the ground.

What kind of analytics can I access with ODIN Checkpoint?

From machine utilization and task completion trends to downtime causes and alert history, ODIN Checkpoint gives you clear, actionable insights to make smarter decisions on the shop floor.

Can ODIN Analytics help reduce downtime?

ODIN Analytics helps you spot patterns, identify root causes, and take action before problems escalate, turning data into smarter, faster decisions on the

ground.

Can I set up custom alerts and KPIs in ODIN Checkpoint?

Yes! With ODIN Checkpoint, you can define the metrics that matter to you and receive real-time alerts tailored to your operation, so you’re always a step ahead.

What's the biggest benefit of using ODIN Analytics over manual tracking?

Manual tracking is slow. It requires double capturing to put data in a digital format, making it more error-prone. ODIN Analytics gives you live, real-time data, helping you make faster decisions without the paperwork.

Can ODIN Checkpoint be deployed in multi-site environments?

ODIN Checkpoint is designed for scalability, making it easy to manage tasks and operations across multiple facilities – all from one central platform.